GALERIJA PALE

20. September 2016.

DUKAT NEKRETNINE

20. September 2016.

- Beograd, Zrmanjska 27

WHAT ARE polypropylene fibers?

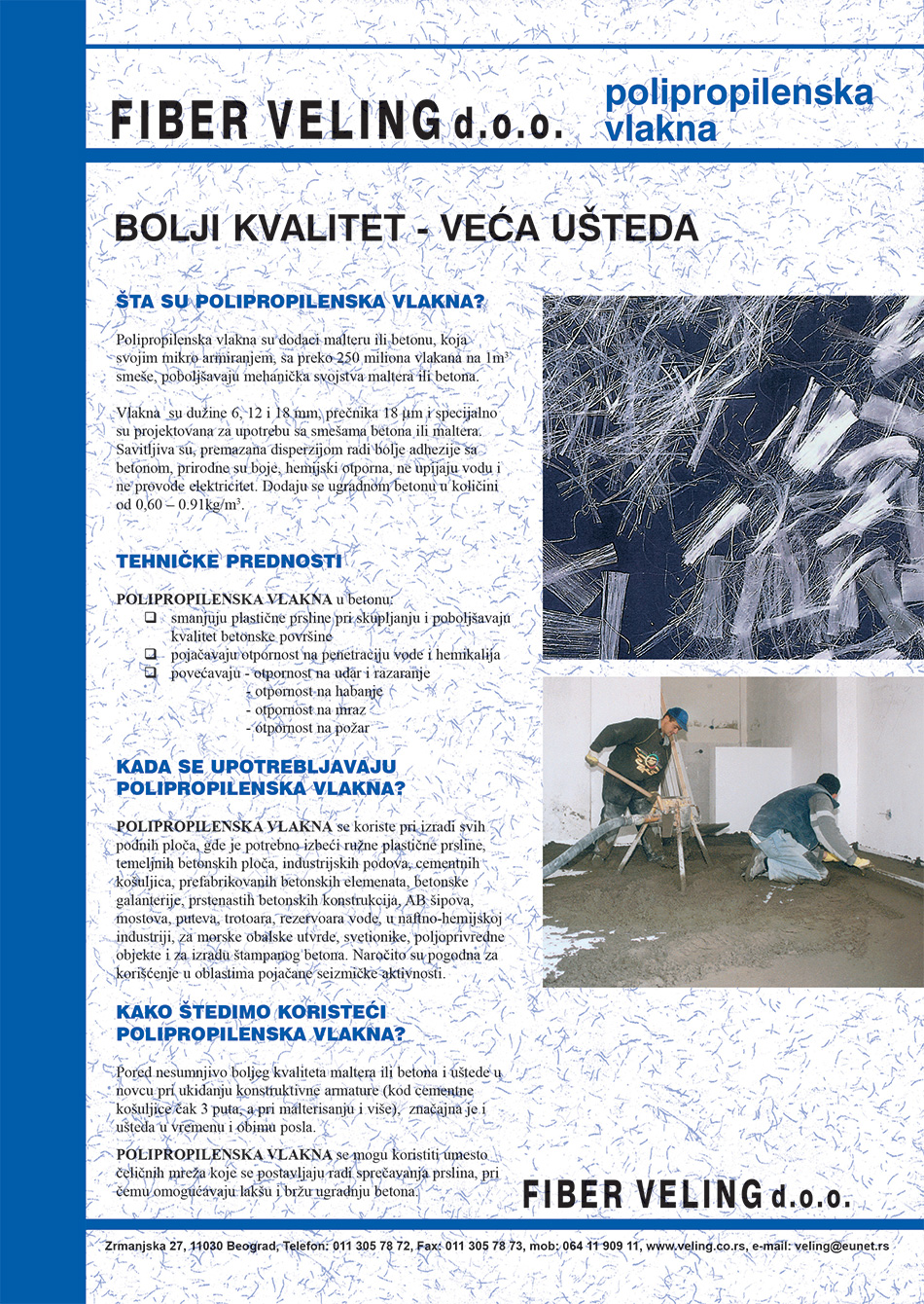

Polypropylene fibers are interior plaster or concrete, which through its micro-reinforcement, with over 250 million fibers per 1m3 mixture, improve the mechanical properties of mortar or concrete. The fibers are long 6, 12 and 18 mm, diameter 18 m and are specially designed for use with mixtures of concrete or mortar. Flexible been coated dispersion for better adhesion to concrete, natural colors, chemical resistant, do not absorb water and do not conduct electricity. Are added to the built-in concrete in an amount of 0.60 – 0.91kg / m3.

TECHNICAL FEATURES

Polypropylene fibers in concrete:

reduce plastic shrinkage cracks and improve the quality of the concrete surface

enhance the resistance to penetration by water and chemicals

increase resistance to shock and destruction

increases the wear resistance

increase resistance to cold

increase fire resistance

WHEN USED polypropylene fibers?

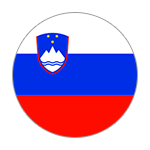

Polypropylene fibers are used in the preparation of floor boards, where it is necessary to avoid ugly plastic cracks, core concrete slabs, industrial floors, cement screeds, precast concrete elements, concrete products, concrete structures ring, AB piles, bridges, roads, sidewalks, water reservoirs in the oil and chemical industry, for marine coastal forts, lighthouses, agricultural buildings and for making stamped concrete. They are particularly suitable for use in areas of increased seismic activity.

HOW TO SAVE USING polypropylene fibers?

Besides undoubtedly better quality mortar or concrete, and save money at the abolition of structural reinforcement (for cement screed even 3 times, and in plastering and more), and significant savings in time and workload. Polypropylene fibers can be used instead of steel mesh, to be installed in order to prevent cracking, while enabling easier and faster installation of concrete.

HAVE CONCRETE look different?

Concrete with polypropylene fibers has a uniform structure than plain concrete. Fitness for work with concrete remains unchanged and is especially important to avoid adding water at any time. The fibers are exceptional fineness and visible only in the fluid state of the concrete.

IS IN LIEU carrying ARMATURE?

Polypropylene fibers can not be used as a substitute for any supporting reinforcement.

Company FIBER VELING Ltd. is a wholesaler of polypropylene fibers and mechanical execution of cement screed. In preparing the cement screed, mixing and transport of the mixture is carried out for the melter pump (miksokretom), a final pargeting “helicopter”. Daily performance with one machine is some 200 – 250 m2 cement screed.

FIBRE BENEFITS VERSUS STEEL NETWORK

Easy installation

It can not be a wrong

Prevents cracking

Extends the durability of concrete

Increases resistance to abrasion

Increases resistance to shock

Increases resistance to frost

Reduces bandwidth

I do not corrode

Reduces cost